iLifterKS – warehouse stocking, storage place optimisation and the loading and unloading of trucks

State-of-the-art 3D camera technology allows precise placement of loads, including a multi-layer stacking option – whether in the rack or on the truck. Using a 360° laser scanner, the fork-lifters orient themselves to predetermined spatial structures. A navigation algorithm reliably filters out changes in the space due to parked vehicles or deposited material. Routes and storage places can be planned independently by the user and storage places can be redefined.

Unlike conventional AGVs and lifting vehicles, the iLiftersKS are mainly designed for automated operation, but can also be operated manually at any time if necessary.

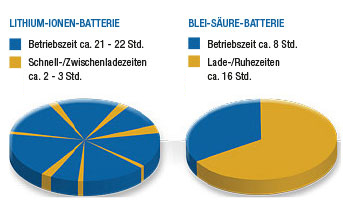

With the globally unique combination of mast compact technology, 4-wheel dynamic steering system – as manoeuvrable as a three-wheeled fork-lifter, hydro-pneumatic level compensation and state-of-the-art, energy-saving lithium-ion high-frequency battery technology for dynamic 24-hour operation, these high-performance fork-lifters set standards in material handling.

iLifterKS Features

- Heavy loads up to 10 t

- 360° laser space navigation

- State of the art camera technology and LIDAR object recognition

- 4 safety laser systems for collision avoidance and personal safety

- Safety control via Safety Wireless Ethernet

- Networked with iMCSKS and error messaging system

- Battery management (optionally lithium-ion or lead-acid batteries)

- Non-contact charging function and efficient battery management

- 4-wheel dynamic steering system

- Hydro-pneumatic level compensation

- Automatic fork-lift tine width adjustment

- Autonomous and manual operation