Intelligent process visualisation and control for assembly, production and autonomous logistics processes

We are solution partners for tailor-made industrial image processing for high-speed applications

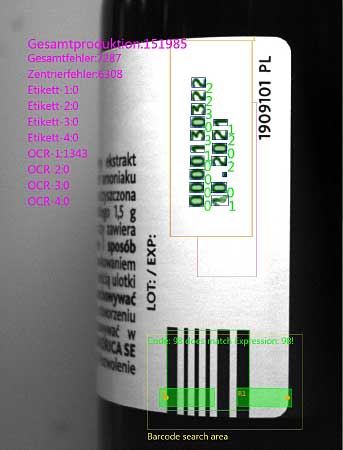

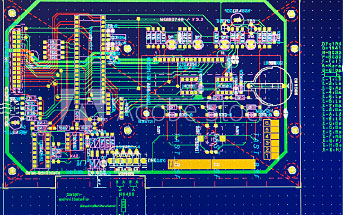

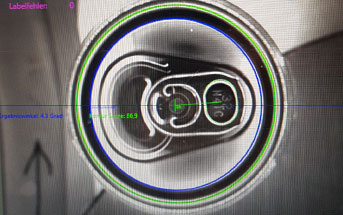

Our specialisation in automation and control includes industrial image processing and customer-specific process control technology. Whether it be fast and intuitive data input for testing and checking requirements, error messaging systems, decentralised monitor screen displays or autonomous logistics solutions with precise product placement, warehouse space optimisation or central control systems: we are partners for optimised man/machine communication.

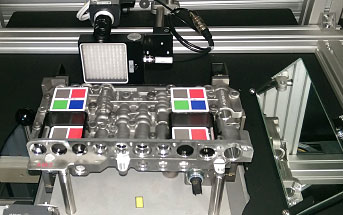

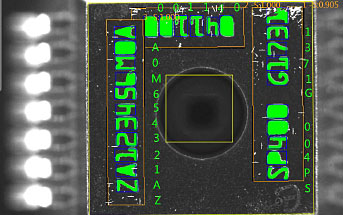

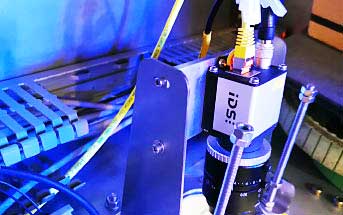

Customer-specific camera and light components

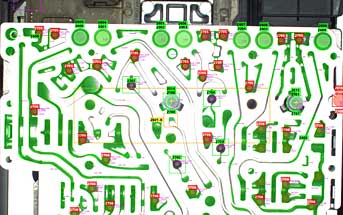

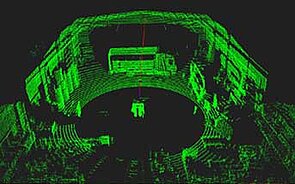

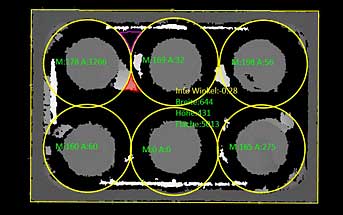

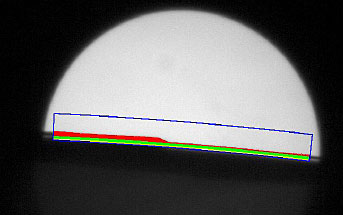

Our individually configurable VISION systems, CCD/CMOS camera systems and LED lighting technology, as well as sensor and laser technology impress with hardware and software from a single source adapted to your needs, customer-specific interfaces and the reliable archiving of data, image and results. In addition to visual camera inspection and control in 2D and 3D, we also implement 3D laser inspection, for example in the case of very complex product geometries in the automotive industry. Our systems are used in product and population inspection, in the automotive industry, in the semiconductor industry, in the food and beverage industry and in logistics.

Our camera and light components:

High-tech individual solutions for maximum detection precision in high-speed use